|

|

|

|

|

|

Support | |

|

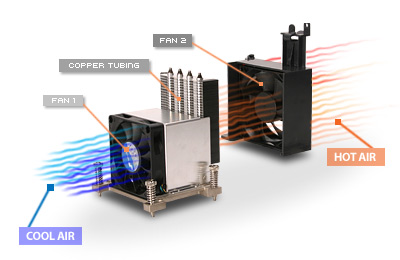

Integrated Cooling Engine and Heatpipe Technology

Shuttle's XPCs offer the power of a desktop PC in a form factor one-third the size. In order to ensure proper airflow inside a smaller unit, more advanced cooling technologies have been developed and implemented in the Shuttle XPC.

Integrated Cooling Engine (I.C.E.) Module

The Integrated Cooling Engine uses heatpipe technology to transfer heat away from the processor and other critical system components. The lower section of the heatpipe modul is a copper plate, which comes into direct contact with the CPU. This is attached with some vacuum-sealed copper pipes which contain very little liquid which is held under low pressure so that the evaporation temperature is just about 30 degrees Celsius. The vaporized fluid creates a pressure gradient which forces the vapor towards the condenser at the other end of the pipes where the working fluid condenses and releases its latent heat to a stack of aluminum fins. The condensed working fluid returns back to the evaporator. In front of the fins is only one large fan to cool both the CPU and system as a whole. The temperature difference between the two ends of the pipe is only a few degrees so it attains a maximum effectiveness of 95%. The heat generated by the CPU is exhausted out of the rear of the chassis without creating additional heat in the rest of the chassis.

I.C.E. Cooling inside P chassis

Every Shuttle XPC uses this patented I.C.E. cooling technology to prevent heat damage and deliver some of the quietest computers in the world. |

|

|

| |

|

|

|

|

|

|

|

|

|

| Búsqueda |

|

|

|

|

|

|

| Shuttle Newsletter |

|

|

|

|

|

Otros usos |

|

|

|

|

|

| El boletín informativo de Shuttle le informa sobre todas las novedades en torno a Shuttle. | |

|

|

|

|